How Brazing Works

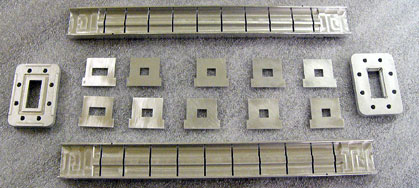

Component parts are cleaned and deoxidized  |

|

|

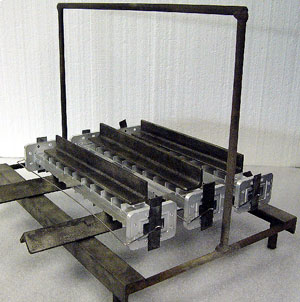

Parts are assembled and fixtured on the brazing rack with brazing filler material preplaced in all joints |

|

Assembled parts are preheated |

|

|

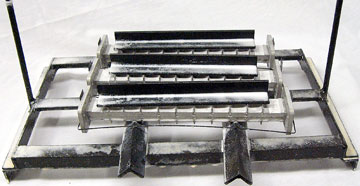

Preheated parts are dipped into the molten brazing flux, raising the entire assembly to brazing temperature and fluxing all joints, simultaneously. The preplaced filler material liquefies and flows throughout the joints by capillary action. |

As parts cool, the filler material solidifies forming brazed assemblies  |

|

|

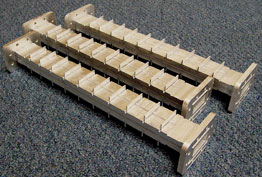

Residual flux is removed from |

|

| Completed, cleaned, brazed assemblies | Optional Chem Film |

|

|